38FSX Folded toolcarrier

Mixing of crop residues

Saving Money

Combining passes

SPADING IS MORE THAN JUST TURNING THE SOIL

More than 60 years of experience with spading

machines is something Imants can look back

on. From that experience we learned spading is

more than just turning soil. Much more, in fact.

Spading means mixing organic material with the

living topsoil, incorporating crop residues and

creating a seedbed, mixing green manure so it

can be broken down into nutrients for the next

crop.

In short, both above the ground and in the soil

you will achieve an even, homogeneous and

well aerated soil after tillage with Imants spading

machines. The true one pass tillage tool.

SUBSOILING, YES OR NO?

SX SERIES

The SX-Series has a minimum working depth of 15 cm (6”), with a maximum of 35 cm (14”). The blades loosen the soil over the entire working width and mix manure, green manure or plant residues through the most biologically active part of the soil.

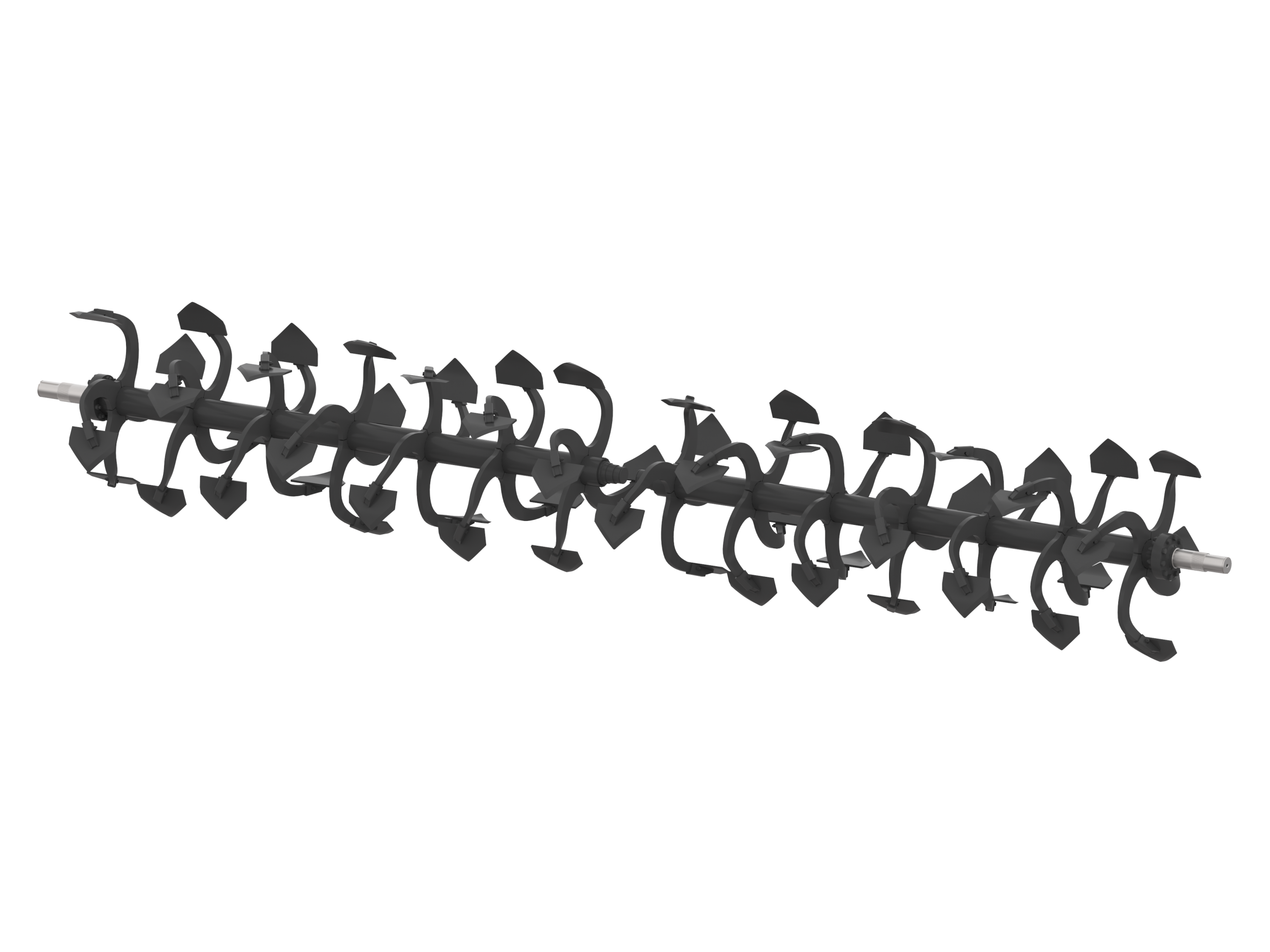

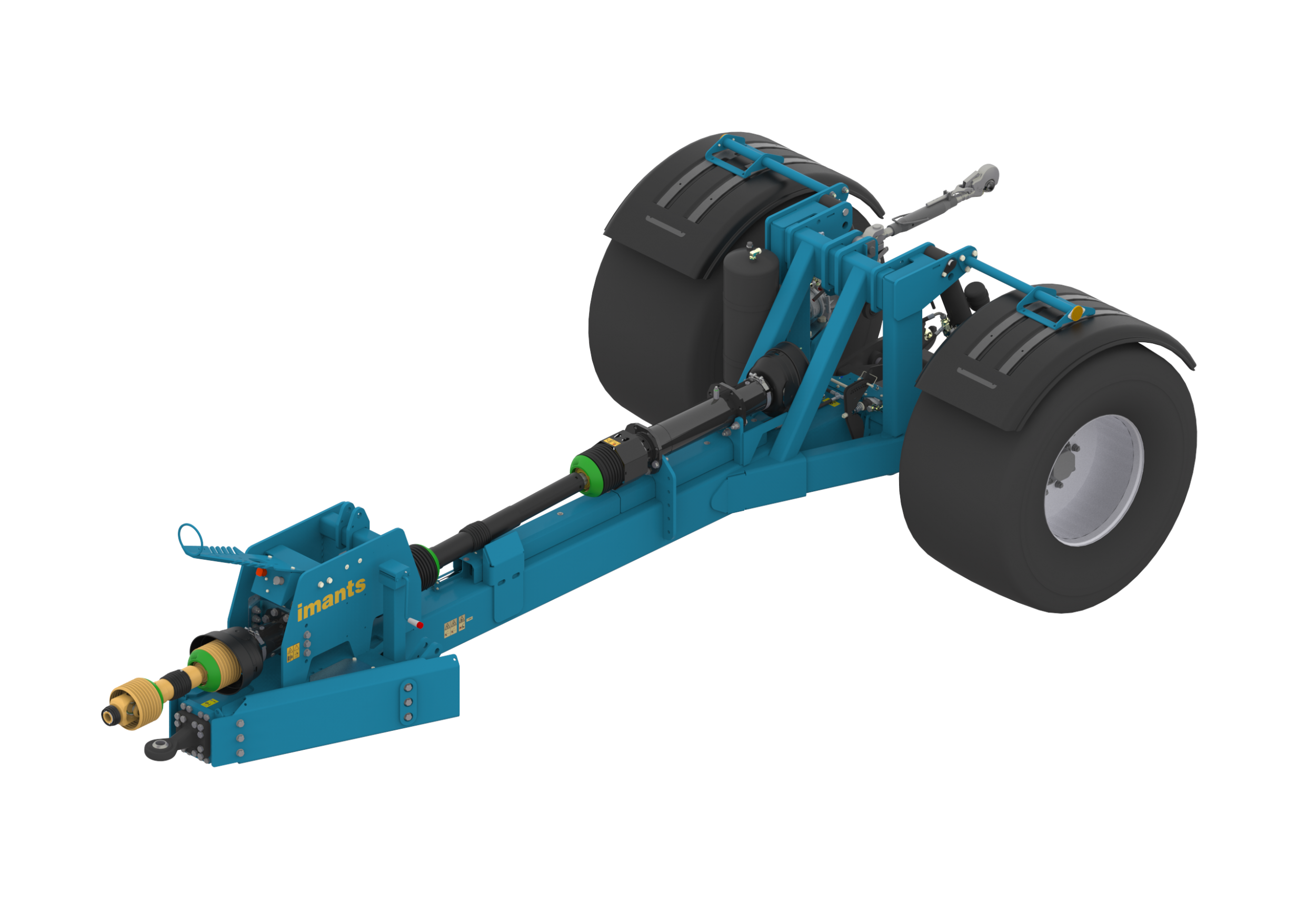

Herewith image of the 38FSX Spading axle.

Optional ripper legs

Optionally both toolcarriers can be equipped with ripper legs. The ripper legs break up compacted layers below the working depth of the spaders The spadeshaft works evenly so that roots can penetrate deeper into the soil. The maximum working depth of the ripper legs is 50 cm (20”).

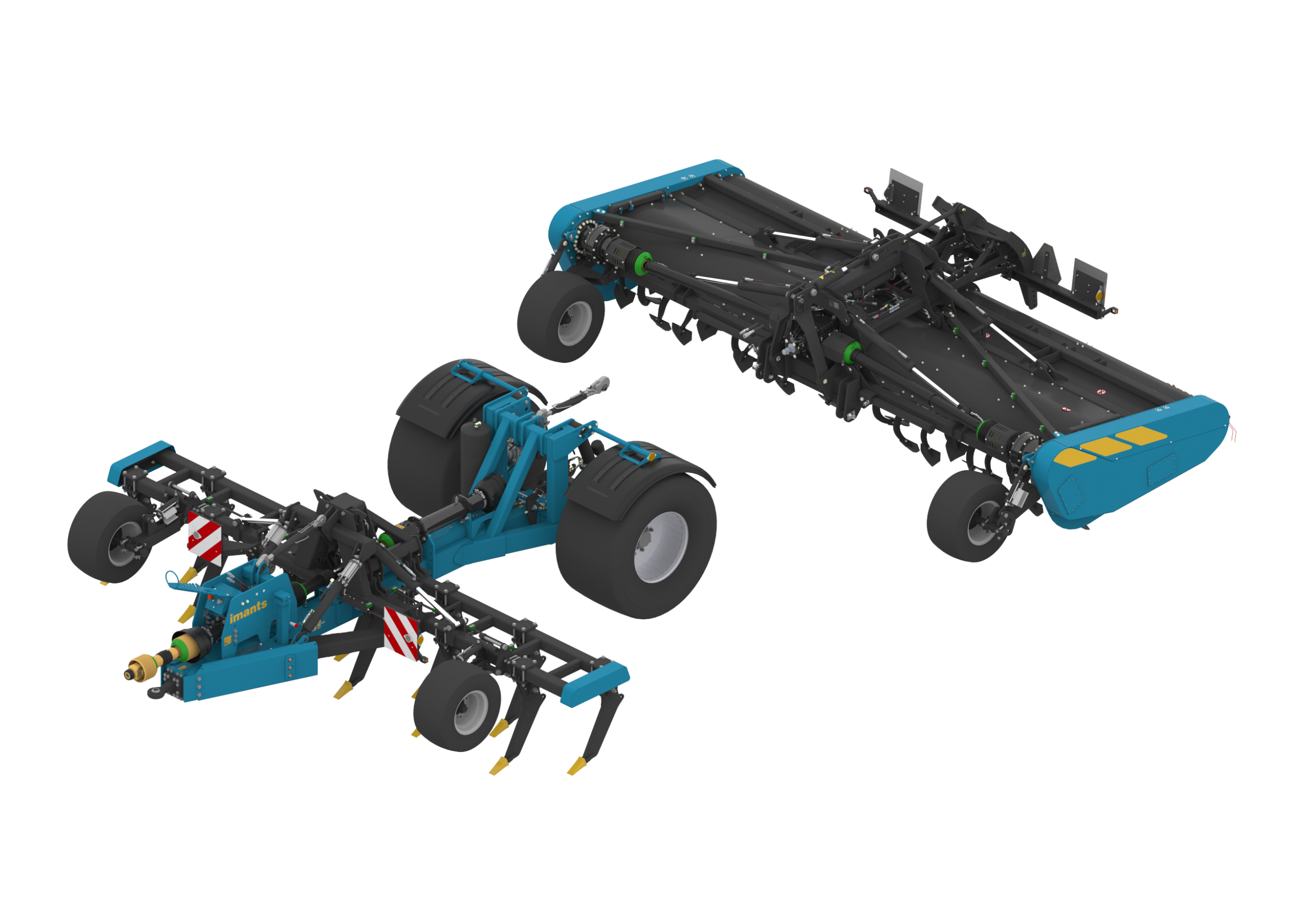

Herewith image of the 38FSX subsoiling beam

WHAT FINISH WOULD YOU LIKE TO HAVE?

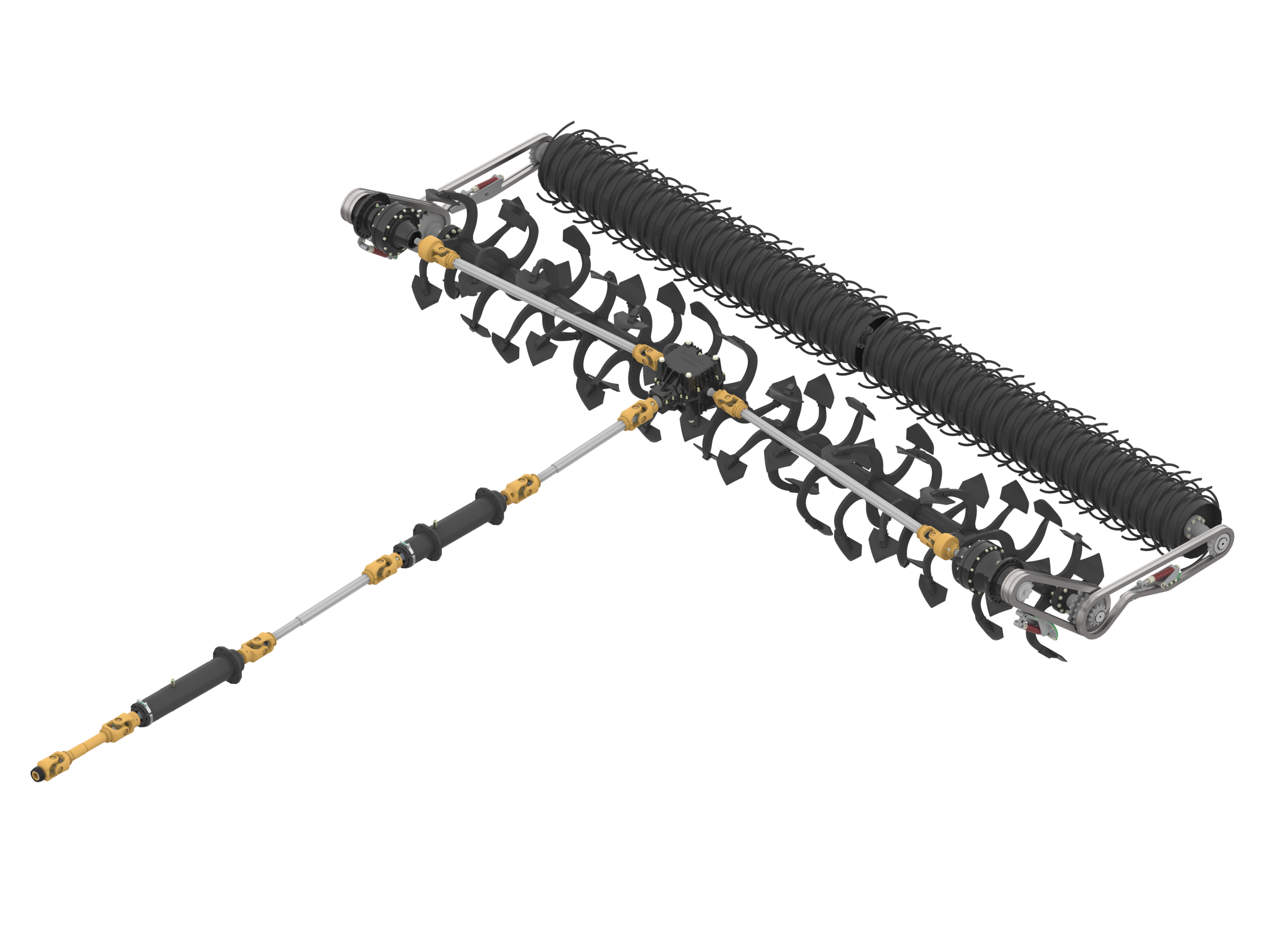

Driven power harrow

The Imants 38FSX and 58 series spading machines can be equipped with a driven power harrow. This harrow breaks up the top layer and ensures a fine and even seedbed. It is the ideal roller for sandy and loamy soils.

Ringroller

The Imants 58 series spading machines can be equipped with a ringroller with a diameter of 60 or 80 cm (24 or 31”). This ringroller leaves a coarser seedbed and is suitable for all soil types.

Prismaroller

For heavier soil types in both dry and moist circumstances, the self-cleaning prismaroller is recommended. This roller consolidates and culti-packs the soil so that an even, flat and firm seedbed is left behind.

Why tool carriers?

The present time makes the demand for larger capacity increasingly important. Through a higher working speed or a larger working width, it is possible to obtain this greater capacity.

However, this makes the tools heavier and often they cannot be lifted in the 3-point linkage of the tractor or they do not comply with road traffic laws.

Imants has therefore developed a tool carrier. Thereby, if desired, a (folding) subsoiler beam can be mounted on the implement carrier allowing multiple work passes to be combined. To save even more time, money and working passes, a seeder can also be mounted.

This makes the tool carrier the heart

of the combination to do all operations

in 1 working pass; subsoiling, spading,

seed bed preparation and seeding.

An enormous cost saving can thus

be achieved. Especially in the current

time where labor is scarce and fuel is

expensive, it is important to take this

into account.

Tractor with a 450 cm (177”) wide rigid subsoiler. Shown with 58SX spading machine with ringroller.

Tool carrier with follble subsoiler and spading machine 600 cm (236”) working width. Shown with 38FSX spading machine, folded in transport position 300 cm (118”) wide.

The construction of the folding trailed spading machine.

In this section, we take a closer look at the tool carrier with folding options. More specifically, the combination with the folding trailed spading machine, 38FSX. This spading machine is available in working widths of 450 or 600 cm (15 or 20 feet), but when folded up, the machine is no wider than 3 meters (10 ft.), making it compliant with the Road Traffic Act, RDW (Dutch) and TÜV (German). The tool carrier with folding subsoiler beam comes standard with this spading machine, but because there is a category III lift at the rear, another PTO driven implement can also be coupled. For example, a power harrow.

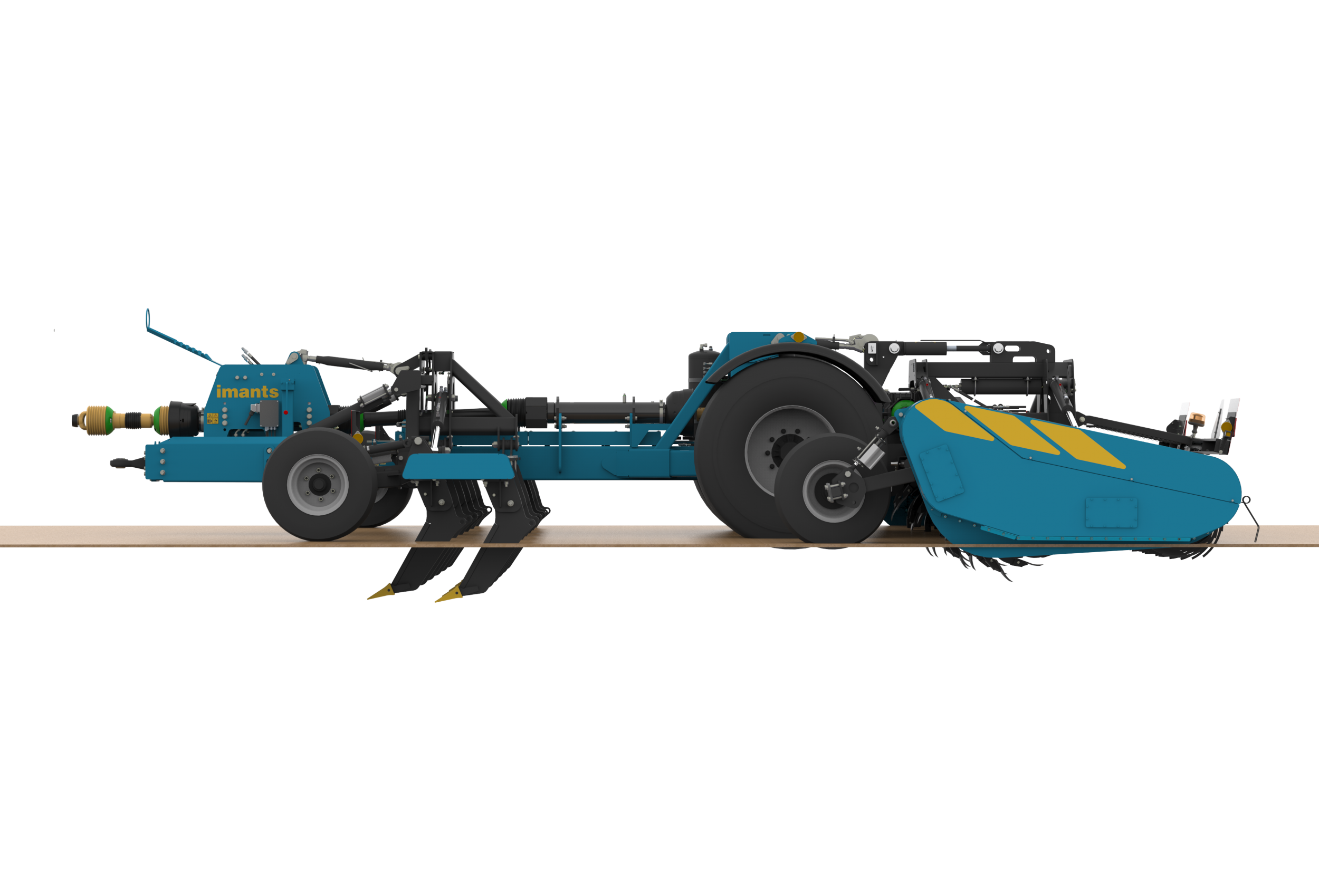

So the 38FSX consists of a tool carrier

with a folding subsoiler beam and a folding

spading machine. The spading machine

works the soil by means of spades

attached to the spading axle via a steel

arm. In the picture a 6-meter (20 ft.) variant

spading axle consisting of two 3-meter (10

ft.) sections. The travel speed is around

6 km/h (3.7 m/h). The working depth of

the subsoiler legs is about 50 cm (20”)

maximum and of the spading machine

about 30 cm(12”) maximum. However,

deeper subsoiling and flatter spading (15-

20 cm / 6-8”) is also possible.

The SX-spadingblade

For use on all soil types

except wet clay.

The spading blades

are easy to replace.

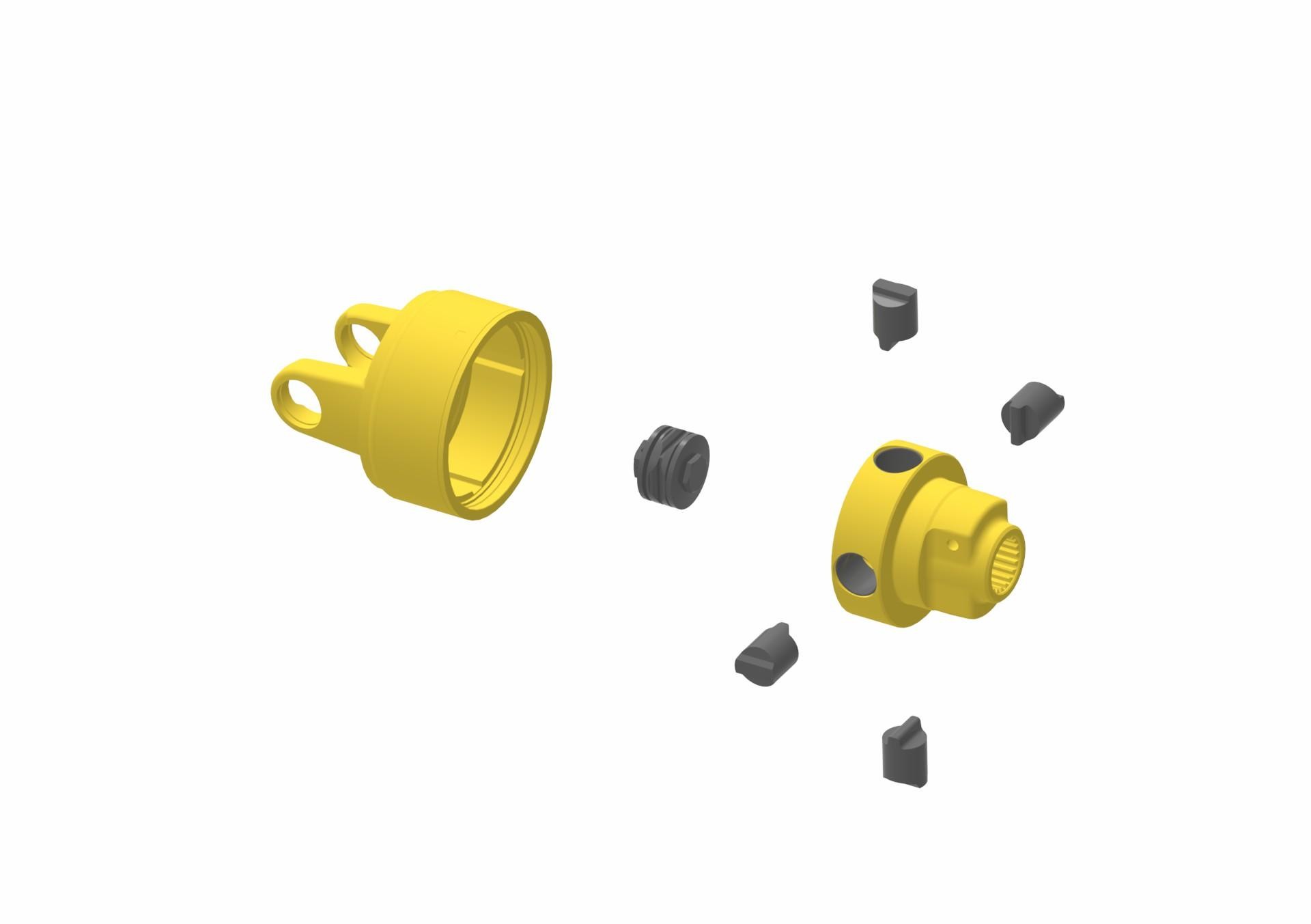

All spading machines are equipped with a torque limiting clutch for protection.

Driveline of the 38FSX600H.

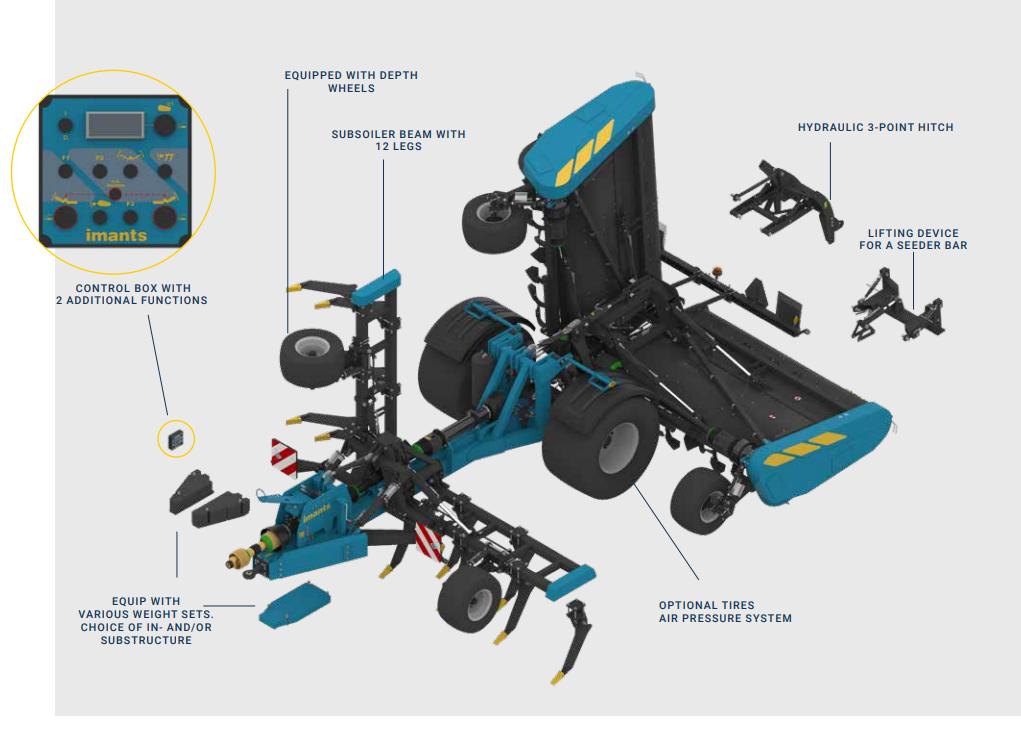

Options for the

tool carrier with

foldable subsoiler

To make the tool carrier fit your business, you can choose from a number of options. The tool carrier with foldable subsoiler has the advantage that, when folded, the transport width is less than 3 meters and is therefore approved for road transport. In combination with the 38FSX spading machine, everything falls within 3 meters (10 ft.). This machine can also be equipped with various hitches. The picture shows, among others, a lift for seeder bar. This is mounted on both halves of the spading machine.

The number of ripper legs can be varied as desired, weights can be added to the drawbar to obtain sufficient drawbar pressure, but also additional hydraulic lines to the rear to operate other implements can be mounted. The control box has room for two more functions. So there are plenty of options to customize the tool carrier to meet your needs.

An optional seed tank (not Imants) can be mounted

as well as coulters. In that case, tilling,

subsoiling, seedbed preparation and

seeding in one working pass.

Saving you time and fuel!

The image shows the 38FSX600H, working width 600 cm (20 ft.).

Contact us for the options of the model of your choice.

The image shows the tool carrier without options.

The 38FSX600H has been chosen as the illustration with 12 subsoiler legs with a working width of 600 cm (20 ft.).

PRACTICAL EXAMPLES TOOL CARRIER WITH FOLDABLE SUBSOILER

The 38FSX can be equipped with different brands of seeders or other implements. Share your wishes and preferences with us and work with your Imants advisor to find the appropriate spading machine combination to meet these needs.

MODELS OVERVIEW

Specifications carrier without options*

|

Type |

Transport- width (cm/inch) |

Working- width (cm/inch) |

Length (cm/inch) |

Max. power driveling (hp) |

Weight (kg / lbs) |

|

Carrier |

295 / 116 |

n.a. |

570 / 224 |

n.a. |

3000 / 6614 |

Specifications carrier with folding trailed spading machine*

|

Type combi Spading machine |

Transport- width (cm/inch) |

Working- Width (cm/inch) |

Length (cm/inch) |

Max. power driveling (hp) |

Weight (kg / lbs) |

|

38FSX450H |

295 / 116 |

450 / 177 |

820 / 323 |

400 |

10000 / 22046 |

|

38FSX600H |

295 / 116 |

600 / 263 |

820 / 323 |

400 |

10700 / 23589 |

*Data based on carrier combined or not with spading machine. For all carriers, the possibility of combining with subsoiler beam and/or seeding as previously mentioned in the relevant option pages applies.

The 38FSX600H with 12 subsoiler legs has been chosen as the illustration. Working depth of the subsoiler legs is (depending on conditions) up to 50 cm (20”) deep. The spading axle and driven power harrow work from 15 to 35 cm (6 to 14”) deep

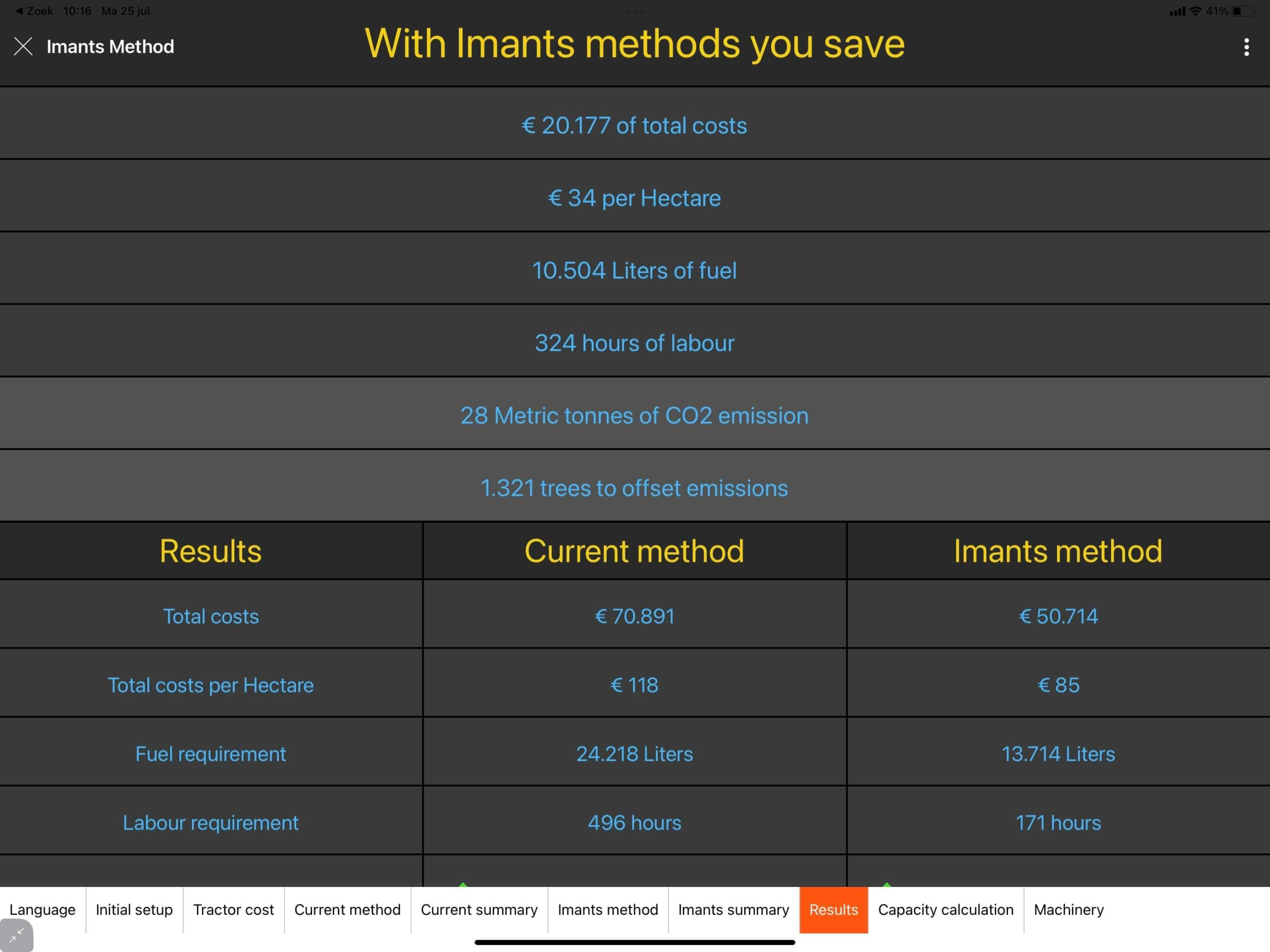

IMCAL

To point out the differences between current tillage methods and Imants tillage methods in

capacity and financial terms, we developed the ImCal app.

In a personal conversation of about one hour, you will be asked about the data of your plot,

current tillage methods, available horsepower and method of depreciation. We will then explain

and calculate the alternative Imants method.

Below is an example of such a calculation.

Don’t wait but ask for a calculation of your situation and start saving!

Want to know more?

Contact us. Call +31 (0)497 - 642 433 or mail to info@imants.nl.