56 series

Reduction of CO2-footprint

Saving Money

Improved rootability

Spading is more than just turning ground

Your land is your wealth. It is the lifeblood of your business. That’s why you want to continuously improve your soil. You want to build it up for the future, for your successors. Imants would like to contribute to that future. More than 60 years of experience with spading machines is something Imants can look back on. From that experience we learned that digging is more than just turning soil. Much more even!

Spading, which mixes organic material with the living topsoil, by working crop residues and green manure into the soil so they can be converted into nutrients. With an Imants spading machine you can also create a seedbed ready to plant in. As a manufacturer, Imants offers you a solution for any tillage requirement. Whether deep or shallow, active or passive, intensive or extensive, mixing or non-mixing, reversible or not.

Read more on spading

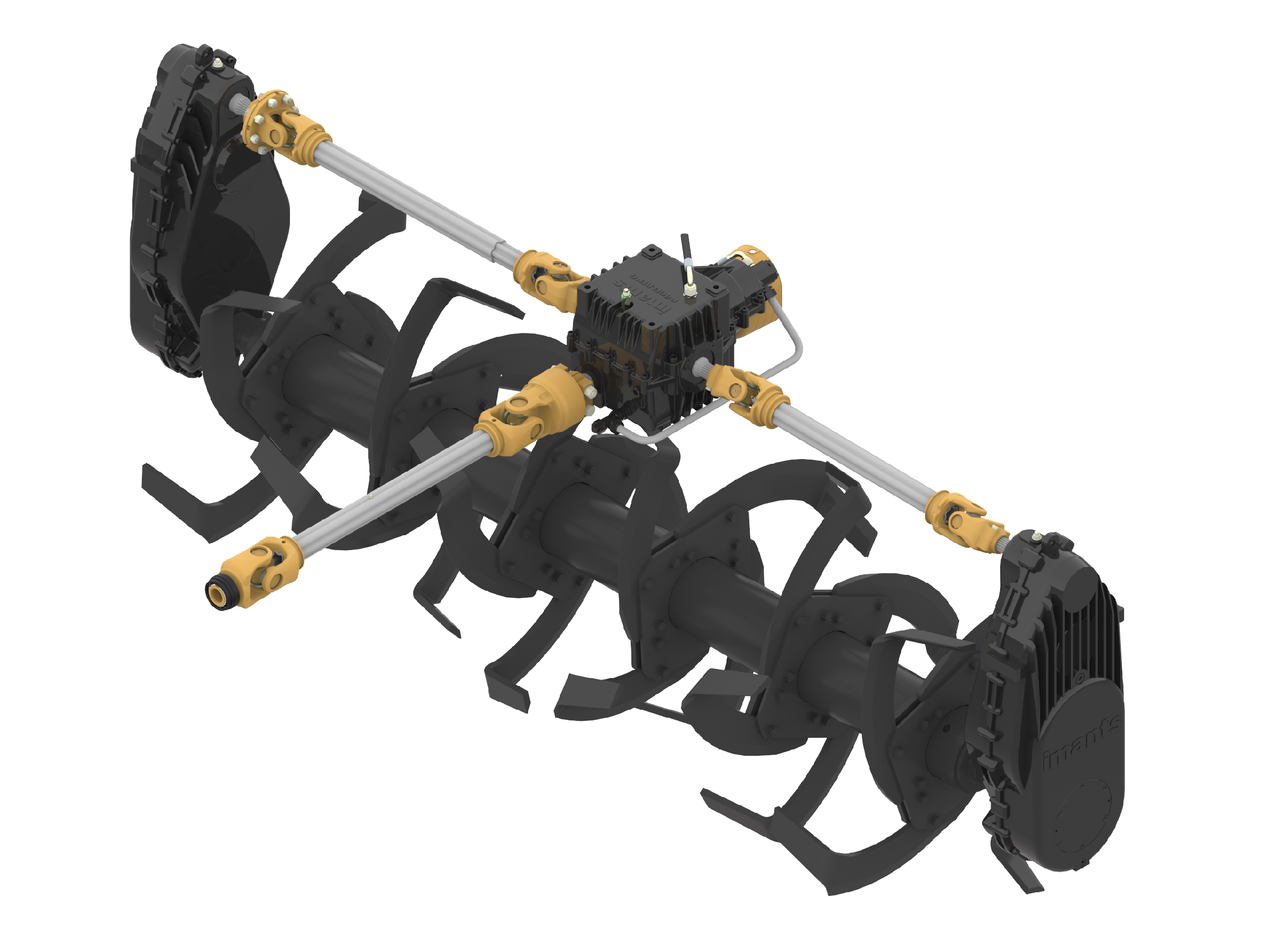

The construction of the rotary spading machine

The spading machines in these series cultivate the soil by means of spading knives bolted to the axle. In both series, 4 knives are mounted to each bank. The number of spade banks varies according to the working width.

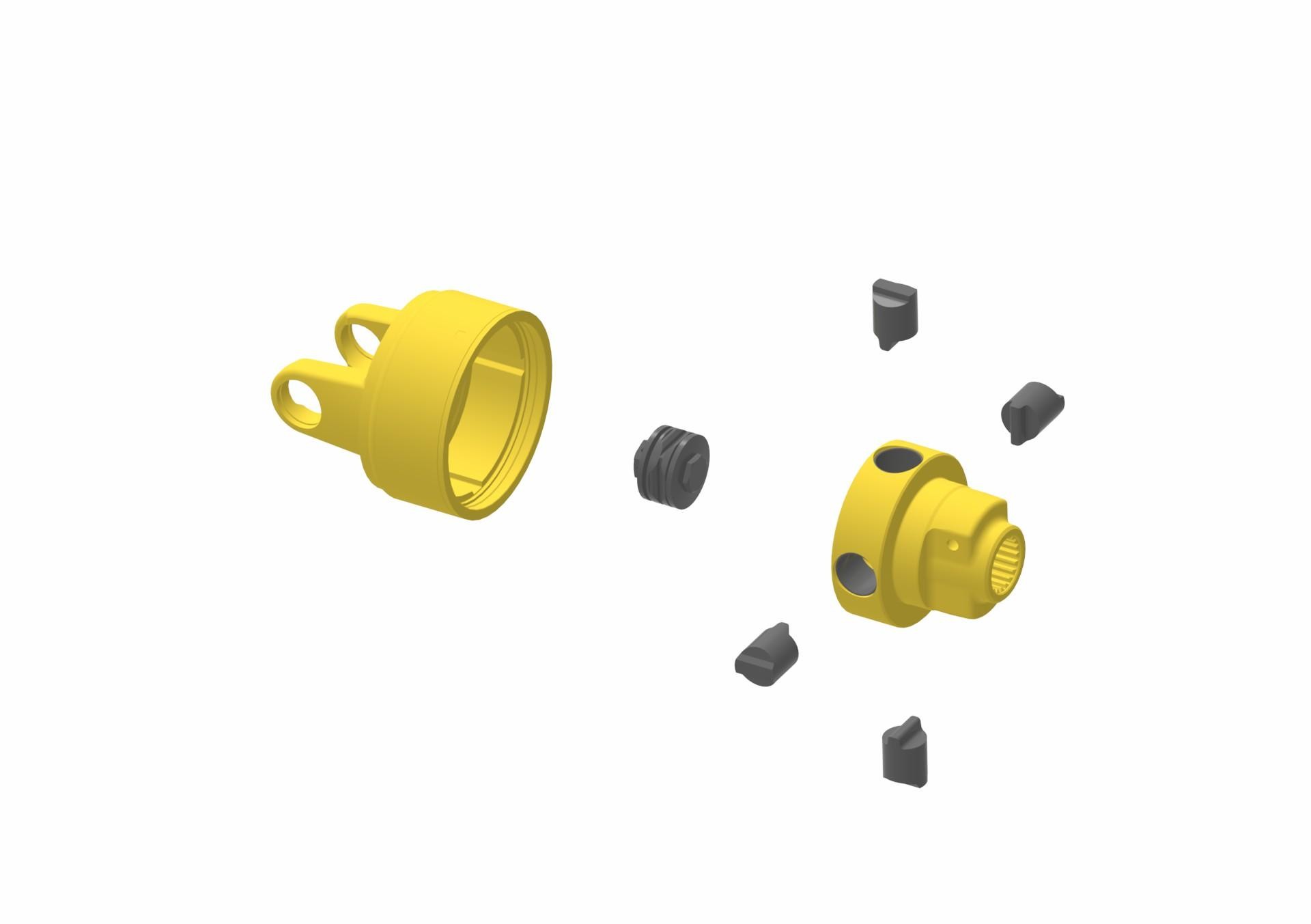

Various spade blades

Depending on your application, various spade blades can be chosen. All of the blade types are bolted on for ease of replacement.

Image of the SPX spade blade, suitable for all soil types blade suitable for all soil types excl wet clay

VX spading knife suitable for clay soil

SM spading knife suitable for clay soil

All spading machines are equipped with a cam clutch on the PTO. This provides protection for the driveline.

Drive line of the 56 Series.

Subsoiling, yes or no?

56 series

The 56 series spading machines have a minimum working depth of 15cm (6 in), maximum is about 35cm (14 in). The spading knives loosen the soil over the entire working width and mix manure, green manure or plant residues through the most biologically active part of the soil.

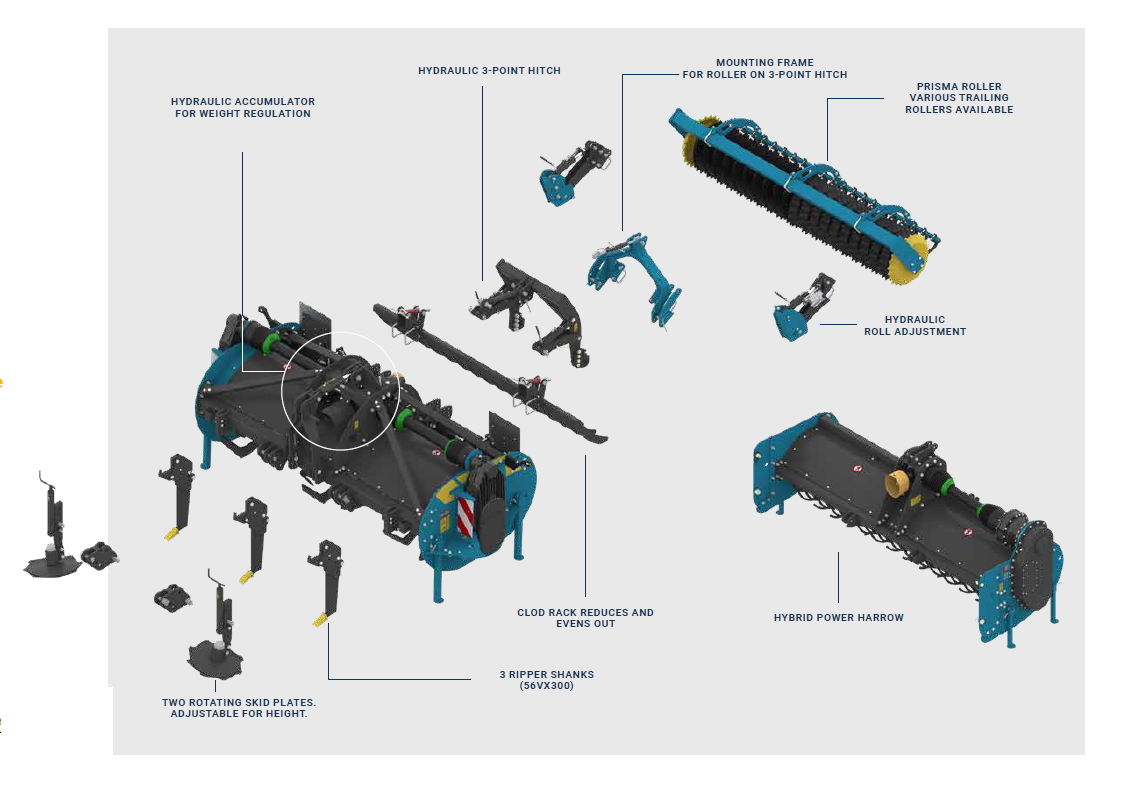

56 series with tine legs

The 56 series spaders can be equipped with depth-adjustable ripper-shanks between the spade banks, which loosen the ground deeper than the spading depth. The shanks ensure that the spader can work with greater ease in hard clay soil. Because of their location between the spade banks, the integrated shanks improve the self cleaning action of the machine. In addition, the shanks break up any existing plow pans that may exist below the spading depth and make sure that roots can penetrate deeper into the soil.

How do you want to leave the land?

Clod breaker

The Imants 56 series spading machines can be equipped with a clod breaker. This clod rack works like a rake, passing small root-balls through and pushing larger ones down and further reducing them. In this way a fine finish is created

Prisma roller

For heavier soil types in both dry and wet conditions, the self-cleaning prisma roller is recommended for the 46 series spading machines. This roller breaks up the surface and lightly compresses the soil leaving a firm level seed bed

Rotor harrow

As an option, the 56 series spading machines can be equipped with a lifting device for a rotor harrow. This rotor harrow goes straight into the ground. After spading, it reduces the soil even further and prepares a seedbed.

Power harrow

The Imants 56 series spading machines can be equipped with a driven power harrow. This roller presses the coarser top layer and creates a fine and even seedbed. It is the ideal roller for sandy and sandy loam soils.

Options for the 56 Series

The 56 series spading machines can be equipped with a clod breaker to further reduce and level the spaded soil. In addition, you can also choose for different types of trailing rollers depending on the soil type. In order to accomodate seeders or planters, these spading machines can also be fitted with a lifting device for combining driven and driven non-powered implements. In order to be able to remove Deeper compacted layers in one pass when necessary, this machine can also be equipped with three ripper shanks. The shanks can be extended or retracted as desired. If this is a standard requirement, then choose the 56WX with five fixed, built-in ripper shanks as standard.

Combining work passes

The 56 series spading machines can be used to prepare the soil for sowing. But the spading machines can also be the heart of combinations to do all the work in one pass. The spader provides primary tillage, loosening and mixing the soil. Mounting other implements like harrows and seeders, allows a true single pass operation. Combining working passes not only saves money and time, but also reduces stress on the soil structure. Here you can see some possible combinations.

Modells overview

| Type | Working width | Overall width | # blades | Required power (hp) | Maximum power (hp) | Weight* | Ripper shanks |

| 56VX300 | 300 cm / 10 ft | 354 cm / 11.5 ft | 24 | 200 | 400 | 2800 kg / 6160 lbs | Option, 3 pieces |

| 56VX350 | 350 cm / 11.5 ft | 404 cm / 13 ft | 28 | 200 | 400 | 3250 kg / 7150 lbs | no |

| 56SX300 | 300 cm / 10 ft | 354 cm / 11.5 ft | 36 | 200 | 400 | 2800 kg / 6160 lbs | no |

| 56WX300 | 350 cm / 11.5 ft | 354 cm / 11.5 ft | 30 | 200 | 480 | 2990 kg / 6578 lbs | 5 pieces |

* Above weight is indicative without options and without roll.

ALL machines include: Walterscheid PTO, scrapers on spading axle (only on 56VX Series).

The 56 Series is equipped with oil cooler as standard

Maximum speed: 5 km/u or 3.1MPH (1000 rpm). Actual travel speed may vary depending on the application.

Digging depth: 15-35 cm (7-14in.)

Want to know more?

Contact us. Call +31 (0)497 - 642 433 or mail to info@imants.nl.